Executive Summary

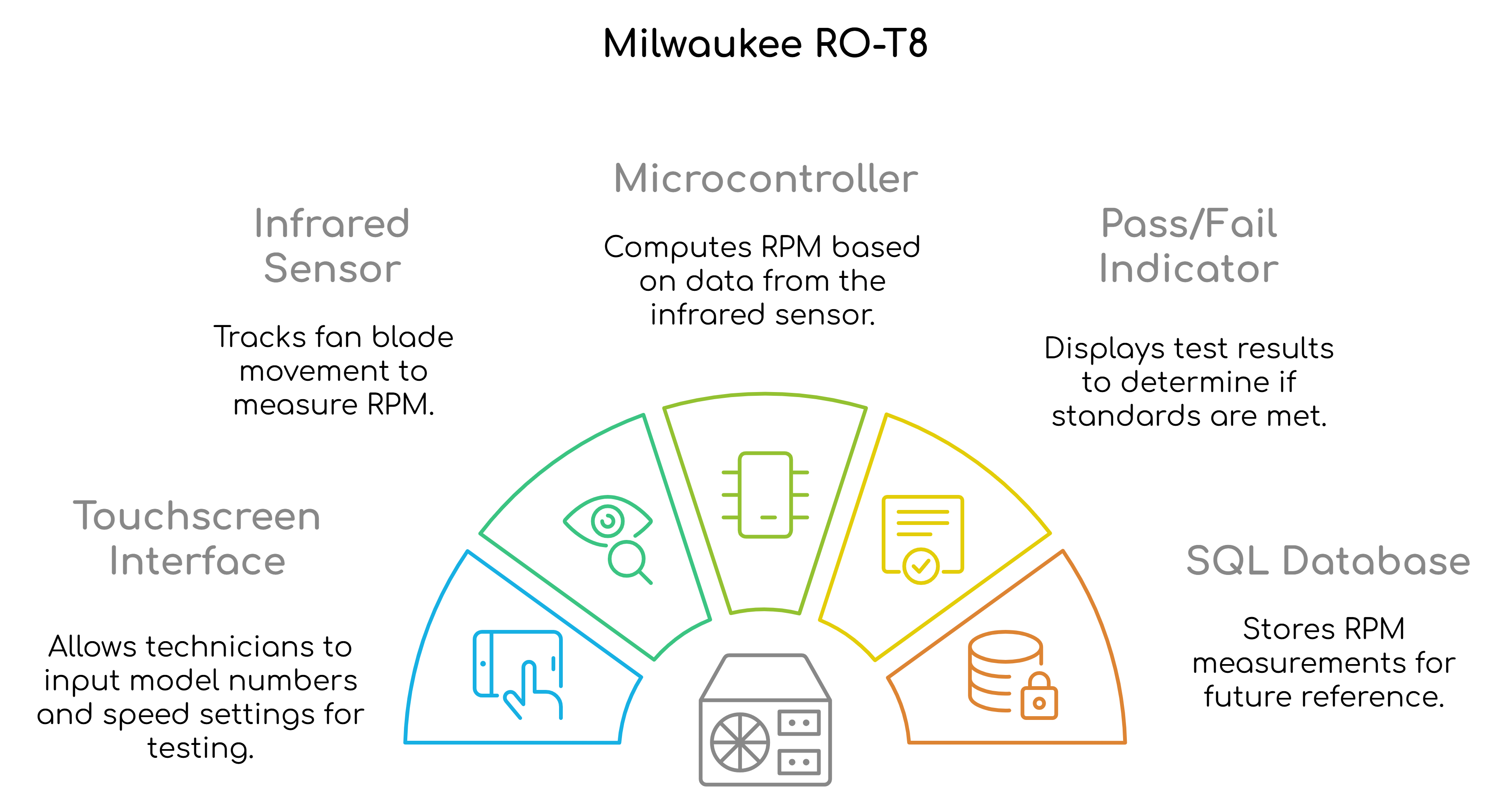

Milwaukee Tool is committed to ensuring that fan repairs are executed correctly and efficiently on the first try. The need to return a device due to an unsuccessful initial repair is an inefficiency that incurs both time and financial costs. To tackle this challenge, Magnolia Electronics has developed the Milwaukee RO-T8. This tool allows technicians to test the RPM of a repaired fan and determine whether it falls within the acceptable range. This verification aids in pinpointing issues or confirming the success of the repair. Additionally, the Milwaukee RO-T8 stores the collected data in a database for future reference and analysis.

The project’s primary design constraints encompassed the budget, size of the technician's test benches, database compatibility, fan model compatibility, and safety. The overall project had an allocated budget of $1000. The Milwaukee RO-T8’s design is compact, requiring minimal space on the 1 x 1.5-meter test benches. It is designed to be compatible with Milwaukee Tool’s existing database, which uses .csv files for data storage. The device is calibrated to measure the RPM of three distinct fan models, each with the same blade count but varying speed requirements. Safety is a critical consideration, ensuring that the design is insulated to safeguard Milwaukee Tool employees from harm.

The Milwaukee RO-T8 employs an infrared (IR) obstacle avoidance sensor to track the movement of the fan blades. The IR sensor detects the frequency at which its line of sight is interrupted by the rotating blades and sends this data to the microcontroller, which computes the RPM based on the number of times the sensor’s beam is broken within a specific period. This non-contact method accurately measures the fan’s RPM. The RPM data is then used to verify whether the fan meets the required standards for the model and speed settings, with the outcome indicated by a pass/fail signal. Additionally, the RPM read-ings are transmitted and stored on an SQL database.

Planned enhancements for the Milwaukee RO-T8 include the integration of a new microcontroller for more precise measurements at higher speeds, further code optimization, and a user interface redesign to enhance usability. Preset sensor placements are also being considered to improve the reliability of the Milwaukee RO-T8. With these upgrades, the Milwaukee RO-T8 is poised to blow away the competition.